Commercial / Industrial Metal Roof Repair & Service

Based in Alberta Delta T. & Protective Products is highly mobile and serves clients across Alberta, Saskatchewan & BC.

Free Metal Roof Repair Consult

To find out if our solutions are right for you call 780-539-5161 or fill out the form below.

*Please note due to a busy summer schedule we may not be able to visit your site for a free consult, but we'll do what we can starting with a phone call.

Delta T Commercial / Industrial Roofing specializes in metal roof repair, maintenance, and coated membranes. We bring 30 years of experience working with galvanized corrugated, standing seam, and other metal roof systems. Our metal roofing services include...

Metal Roof Repair #Urgent

If your roof is leaking and you need a fix now, we’ll assess the situation for free and show you your options. Sometimes a quick repair is all that’s needed, sometimes the scope is more complex. If you’re leaking, call us now at 780-539-5161 and we’ll do whatever we can to help.

Metal Roof Maintenance #Preventative

Most roof leaks are predictable and preventable. Building owners tend to learn this the hard way and only find out their vulnerable when the water starts pouring in. If you have a minor leak now or think your roof might be vulnerable we encourage you to take us up on our FREE, no-obligation inspection. We’ll check your roof seams, penetrations, and fasteners and show you how to get ahead and stay ahead of costly repairs in the future.

Metal Roof Membrane #Restorative

Metal roofs expand and contract as temperatures fluctuate causing fasteners, seams, and penetrations to shift and become vulnerable points of leakage. In Western Canada, the harsh cold winters and the increasingly hot summers make this a significant problem for building owners. Our proprietary coating membrane protects your roof in two significant ways.

1. The membrane acts as a seamless skin covering your entire roof, sealing your existing points of leakage and protecting against future problems.

2. The coating itself becomes a thermal barrier drastically reducing the impact of extreme temperature fluctuations, minimizing the expansion, contraction, and shifting of your roof.

*Please note due to a busy summer schedule we may not be able to visit your site for a free consult, but we'll do what we can starting with a phone call.

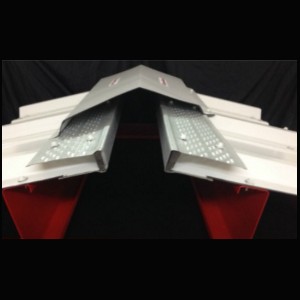

Ventilated Ridge Cap for Metal Roofs #Performance

If you’ve ever noticed condensation forming on the inside of your metal roof, poor ventilation is likely the cause. Ventilated ridge caps are a fantastic solution that will improve the performance and longevity of your structure and reduce the risk of damage caused by condensation.

Rain Gutter Leaf Guards #Preventative

An effective gutter system ensures rainwater ends up exactly where it’s supposed to. When leaves and debris clog your gutters, rainwater will find somewhere else to go often resulting in costly flooding or property damage. Gutter guards keep leaves and debris from collecting and prevent flooding and damage. Guards will extend the life of your gutters and prevent costly repairs or replacements in the future.

Rain Gutter Cleaning & Maintenance #Routine

Like any other part of your building, proactive gutter cleaning and maintenance can extend the life of your system and prevent costly repairs or damage. We’ll clean your gutter, inspect it for damages, and recommend a maintenance schedule.

Snow and Ice Guards #Preventative

Snow and ice sliding off your metal roof is a safety and liability concern. We can install guards that will prevent the snow and ice from falling and reduce the risk of injury or property damage.

Skylight Repair & Maintenance

People love the natural sunlight skylights provide. However, they can become sources of leakage, ice damming, energy loss, or ventilation issues. If you have a skylight that’s leaking or causing other issues, we’ll inspect it and recommend the best course of action.